Your shopping cart is currently empty.

€1,093.13

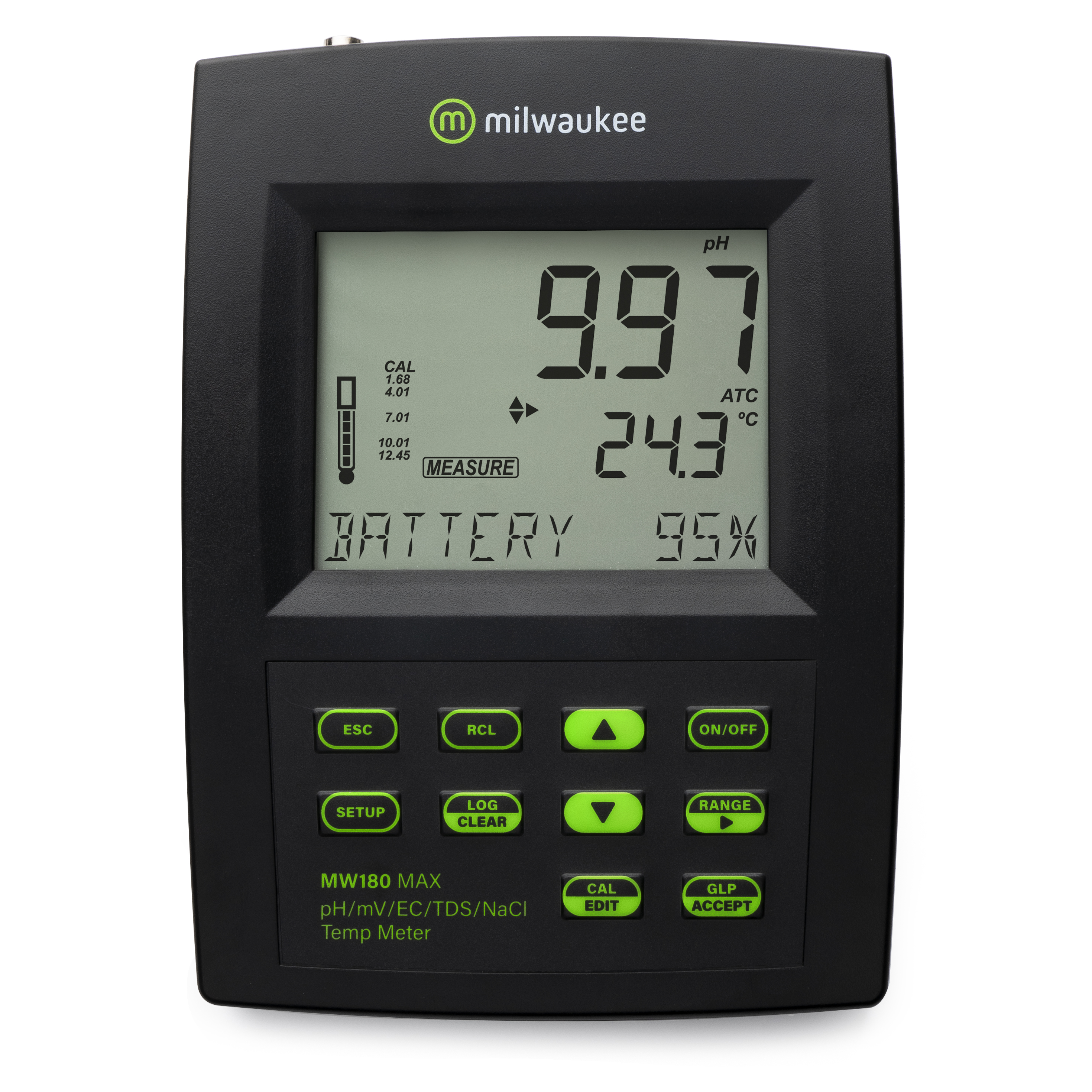

Milwaukee MW180 MAX pH/mV/EC/TDS/NaCl/Temp Bench Meter with Logging

Milwaukee MW180 MAX pH/mV/EC/TDS/NaCl/Temp Logging Bench Meter – Professional Multi-Parameter Precision

A Complete Solution for Multi-Parameter Water Analysis

In professional environments where accuracy and reliability are non-negotiable, water quality testing requires more than just a simple pH reading. From laboratories to industrial plants, from environmental monitoring to food and beverage production, professionals need an instrument that can deliver multi-parameter analysis with uncompromising precision.

The Milwaukee MW180 MAX Bench Meter has been engineered for this very purpose. Designed for scientists, engineers, technicians, and quality assurance specialists, the MW180 MAX measures pH, ORP (mV), electrical conductivity (EC), total dissolved solids (TDS), salinity (NaCl), and temperature – all from a single compact instrument. Its data logging function enables accurate recordkeeping and traceability, ensuring full compliance with regulatory standards and industry best practices.

With intuitive operation, advanced calibration options, and durable probes built for heavy use, the MW180 MAX combines cutting-edge measurement technology with the practical features professionals demand. Whether you are running a laboratory, managing water treatment, or overseeing food quality control, the MW180 PRO brings confidence, repeatability, and efficiency to your daily testing routines.

Why Choose the Milwaukee MW180 MAX?

- All-in-One Multi-Parameter Capability: Accurately measure pH, ORP, EC, TDS, NaCl, and temperature in one device.

- Data Logging & Traceability: Store up to 1,000 data points with GLP-compliant information for easy retrieval and reporting.

- High Accuracy: Achieve laboratory-grade precision with automatic or manual temperature compensation.

- User-Friendly Interface: Large, easy-to-read backlit LCD with intuitive navigation and clear parameter displays.

- Flexible Calibration: Automatic buffer recognition with up to 5-point pH calibration and multiple EC calibration standards.

- Durable Probes Included: Supplied with professional-grade electrodes designed for long life and demanding environments.

- USB Connectivity: Download stored measurements quickly for analysis and archiving.

- Versatile Power Supply: Works with an AC adapter or standard batteries for portability and reliability.

Versatile Applications of MW180 MAX

Advanced Laboratories & Research

- Multi-parameter testing for water chemistry, environmental science, and industrial R&D

- Data logging supports compliance, reproducibility, and scientific accuracy

Water Treatment & Environmental Monitoring

- Monitoring pH, EC, TDS, and salinity in drinking water, wastewater, and natural water bodies

- Ensuring compliance with international water quality standards

Food & Beverage Production

- Brining, fermentation, and quality control in beer, wine, dairy, and food processing

- Salinity (NaCl) and conductivity management for flavor, safety, and consistency

Hydroponics & Commercial Horticulture

- Managing nutrient solutions with pH, EC, TDS, and temperature tracking

- Logging trends to optimize crop growth and prevent nutrient lockout

Aquaculture & Marine Systems

- Stable monitoring of pH, ORP, and salinity for aquariums, fish farms, and coral reefs

- Protecting sensitive species in both freshwater and marine environments

Industrial Water Management

- Multi-parameter control in boilers, cooling towers, and chemical processes

- Preventing corrosion, scaling, and efficiency loss through continuous monitoring

Specialized Applications

- Desalination plants monitoring salinity and conductivity

- Pharmaceutical and biotech industries requiring stringent water quality assurance

- Educational institutions training students in applied water chemistry

Proper Care & Maintenance

Your MW180 MAX is built for reliability, but proper care of the electrodes is essential for maintaining long-term accuracy.

- Storage: Always keep the pH electrode hydrated in proper storage solution or pH calibration buffers. Never store in tap or distilled water. Use the probe cap filled with storage solution to prevent drying and clogging.

- Cleaning: Regularly clean electrodes, especially when used in samples with organic matter, brines, or nutrient solutions. Soak in specialized cleaning solution to restore sensitivity.

- Calibration: Perform frequent calibration to ensure accuracy. The MW180 MAX supports up to 5-point calibration for pH and multiple EC calibration standards. Always calibrate after cleaning or extended storage.

- Handling: Avoid touching the sensitive glass bulb of the pH electrode. Handle probes carefully to extend their lifespan.

By following these care practices, you ensure your MW180 MAX continues to deliver precise, reliable, and professional-grade measurements for years to come.

With its combination of multi-parameter capability, logging, and professional-grade accuracy, the Milwaukee MW180 MAX is more than a meter – it’s a complete solution for those who demand the highest standards in water quality analysis.

Specifications

Application

Advanced Laboratories & Research

In modern laboratories and research facilities, precision and repeatability are critical. The Milwaukee MW180 MAX Bench Meter is engineered for scientists, technicians, and quality control specialists who require multi-parameter water analysis in a single, reliable instrument. With the ability to measure pH, oxidation-reduction potential (ORP/mV), electrical conductivity (EC), total dissolved solids (TDS), salinity (NaCl), and temperature, the MW180 PRO eliminates the need for multiple devices, reducing both cost and complexity.

For universities, academic training labs, and research institutes, the MW180 MAX serves as a versatile teaching tool. Students can learn how different parameters interact – for example, how pH, EC, and TDS influence nutrient availability, or how salinity and ORP play a role in environmental water studies. Its data logging function (up to 1,000 records) ensures compliance with Good Laboratory Practice (GLP), supporting traceability, audits, and peer-reviewed publication requirements.

In regulated industries such as pharmaceuticals, biotechnology, and environmental monitoring, the MW180 MAX provides the level of accuracy and documentation required for ISO, EPA, and GMP compliance. Researchers can monitor pH stability in chemical reactions, measure salinity in brine samples, or track conductivity changes in purified water systems, all while maintaining a clear audit trail for quality assurance.

By combining multiple parameters into one compact bench meter, the MW180 MAX not only improves efficiency but also ensures consistency across repeated measurements, making it indispensable for scientific research, laboratory testing, and applied water chemistry education.

How to Use the MW180 MAX in Laboratories & Research

1. Setup & Calibration

o Connect the professional-grade electrodes (pH, ORP, EC/TDS/NaCl, temperature).

o Perform a multi-point calibration (up to 5 points for pH, multiple standards for EC) using certified calibration solutions.

o Ensure automatic temperature compensation (ATC) is enabled for maximum accuracy.

2. Measurement Process

o Place the electrodes into the prepared sample (water, nutrient solution, brine, or experimental medium).

o Wait for the readings to stabilize – the large backlit LCD will display pH, ORP, EC, TDS, NaCl, and temperature simultaneously.

o Record readings manually or use the data logging feature to automatically save results with timestamp and calibration history.

3. Data Management & Traceability

o Store up to 1,000 measurements in the meter’s memory, complete with GLP-compliant information.

o Export stored data via USB connection to a computer for analysis, reporting, or archiving.

o Use logged data to compare experimental results, track trends, or verify compliance with laboratory standards.

4. Best Practices

o Use fresh calibration buffers and storage solution for the pH electrode.

o Rinse probes with deionized water between samples to avoid contamination.

o Log data regularly to ensure a complete record for audits or research publication.

With its multi-parameter capability, data logging, GLP compliance, and high precision, the Milwaukee MW180 MAX is more than just a laboratory bench meter – it is a comprehensive research tool for universities, regulated industries, and advanced scientific applications.

Water Treatment & Environmental Monitoring

Maintaining safe and compliant water quality is one of the most important challenges faced by municipal water treatment plants, wastewater facilities, and environmental agencies. The Milwaukee MW180 MAX Bench Meter delivers professional-grade multi-parameter water analysis, making it the ideal tool for ensuring regulatory compliance, monitoring environmental impact, and improving process efficiency.

The MW180 MAX provides precise measurement of pH, oxidation-reduction potential (ORP/mV), electrical conductivity (EC), total dissolved solids (TDS), salinity (NaCl), and temperature – six critical parameters that directly affect water quality and safety. By combining all of these into a single instrument, the MW180 MAX streamlines operations, reduces the need for multiple devices, and ensures consistent, reliable results.

For drinking water facilities, accurate pH and conductivity testing ensures compliance with EPA, WHO, and EU water quality standards, protecting public health. In wastewater treatment plants, monitoring ORP levels helps optimize disinfection processes and chemical dosing, while TDS and salinity tracking provide insight into treatment efficiency.

Environmental agencies and research institutions rely on the MW180 MAX for field and lab-based environmental water testing. From monitoring rivers, lakes, and groundwater to assessing the impact of industrial discharge, this bench meter delivers the precision required for long-term environmental monitoring programs. Its data logging function allows professionals to track changes over time, identify trends, and generate reports that support decision-making and compliance audits.

Whether used in municipal water treatment, industrial process control, or environmental resource management, the MW180 MAX ensures that pH, EC, TDS, NaCl, ORP, and temperature are all monitored with accuracy, consistency, and traceability.

How to Use the MW180 MAX for Water Treatment & Environmental Monitoring

1. Setup & Calibration

o Connect the supplied electrodes for pH, ORP, EC/TDS/NaCl, and temperature.

o Perform multi-point calibration using certified calibration standards (pH buffers, EC calibration solutions).

o Enable Automatic Temperature Compensation (ATC) to ensure reliable results in varying conditions.

2. Sampling & Measurement

o Collect water samples in clean containers from treatment plants, rivers, lakes, or wells.

o Immerse the electrodes in the sample and wait for stable readings on the LCD display.

o Simultaneously record pH, ORP, EC, TDS, salinity, and temperature values for a complete water quality profile.

3. Data Logging & Compliance

o Store up to 1,000 measurements directly in the meter with full GLP-compliant calibration history.

o Export results via USB connection for integration into compliance reports, audits, or environmental studies.

o Use logged data to track changes in water quality over time and demonstrate compliance with local and international regulations.

4. Best Practices

o Rinse probes with deionized water after each sample to prevent cross-contamination.

o Regularly calibrate probes, especially when switching between different water types (e.g., treated water vs. wastewater).

o Log data consistently to create a reliable long-term record for audits and environmental reporting.

With its ability to deliver multi-parameter water testing in one compact system, the Milwaukee MW180 MAX is a trusted choice for drinking water safety, wastewater management, and environmental monitoring programs worldwide.

Food & Beverage Production

In the food and beverage industry, water quality and process monitoring directly affect taste, safety, and product consistency. The Milwaukee MW180 MAX Multi-Parameter Bench Meter is specifically designed to meet these challenges by providing precise measurement of pH, ORP, EC, TDS, NaCl, and temperature – six critical parameters for fermentation, brining, and food processing applications.

For breweries and wineries, maintaining the right pH and temperature during fermentation ensures yeast performance, flavor development, and product stability. In dairy processing, monitoring acidity and conductivity is essential for consistent texture and taste in products like yogurt and cheese. Pickling and canning operations rely on accurate salinity (NaCl) measurement to preserve flavor and extend shelf life, while ensuring compliance with food safety regulations.

The MW180 MAX also plays a crucial role in HACCP (Hazard Analysis and Critical Control Points) programs, where traceability and compliance are mandatory. With its data logging capacity of up to 1,000 records and GLP-compliant calibration history, the MW180 MAX supports food manufacturers in documenting critical control points, preparing for audits, and ensuring full traceability from production to packaging.

Whether you are managing a craft brewery, a commercial dairy plant, a winery, or a food preservation facility, the MW180 MAX delivers lab-grade accuracy, repeatability, and compliance-ready data logging, making it an indispensable tool for modern food quality assurance.

How to Use the MW180 MAX in Food & Beverage Production

1. Setup & Calibration

o Connect the electrodes for pH, ORP, EC/TDS/NaCl, and temperature.

o Calibrate with food-safe calibration solutions (pH 4.01, 7.01, and 10.01 buffers; EC standards; NaCl calibration solution).

o Ensure ATC (Automatic Temperature Compensation) is active to guarantee accurate readings in varying production environments.

2. Measurement Process

o Fermentation: Place the electrodes directly in fermentation tanks or use sample beakers to measure pH and temperature at different fermentation stages.

o Brining & Pickling: Test brine solutions for salinity (NaCl), pH, and conductivity, ensuring optimal preservation and flavor.

o Dairy Processing: Measure acidity (pH) and conductivity in milk and dairy mixtures to monitor stability and product consistency.

o Canning & Food Processing: Verify TDS and salinity levels in preservation liquids to ensure compliance with safety standards.

3. Data Logging & Compliance

o Record measurements automatically using the MW180 MAX’s built-in data logging function.

o Export results via USB connection for integration into HACCP records and quality assurance reports.

o Maintain GLP-compliant calibration history to support audits and traceability requirements.

4. Best Practices

o Rinse probes with distilled water between samples to prevent contamination across batches.

o Store electrodes in appropriate storage solutions when not in use to preserve accuracy.

o Schedule regular calibration, especially when switching between acidic, salty, or dairy-based samples.

With its multi-parameter measurement, HACCP-friendly logging, and precision calibration, the Milwaukee MW180 MAX empowers food and beverage producers to achieve consistent flavor, reliable preservation, and full compliance with safety regulations – from artisanal brewing to large-scale food manufacturing.

Hydroponics & Commercial Horticulture

In hydroponics, vertical farming, and commercial horticulture, water chemistry defines the success of every crop. The Milwaukee MW180 MAX Multi-Parameter Bench Meter is an essential tool for growers who need complete nutrient solution management to achieve maximum yields, consistent quality, and reduced losses.

With the ability to measure pH, electrical conductivity (EC), total dissolved solids (TDS), salinity (NaCl), oxidation-reduction potential (ORP), and temperature, the MW180 MAX gives growers a full picture of their water and nutrient solution. pH control ensures nutrient availability and prevents lockout, while EC and TDS measurements verify the concentration of dissolved nutrients. Salinity (NaCl) levels can be tracked to prevent salt buildup, which can damage root systems, and temperature readings help optimize nutrient uptake.

For commercial greenhouses, hydroponic farms, and indoor grow operations, the MW180 MAX provides multi-parameter accuracy and long-term data logging. With up to 1,000 logged measurements, growers can track trends over entire growth cycles, adjust feeding schedules, and optimize irrigation. This historical data also supports predictive adjustments, allowing growers to fine-tune nutrient dosing before imbalances occur.

By integrating the MW180 MAX into daily operations, professional growers gain a laboratory-grade water quality meter that helps them reduce costs, improve efficiency, and consistently deliver high-value crops.

How to Use the MW180 MAX in Hydroponics & Commercial Horticulture

1. Setup & Calibration

o Connect the electrodes for pH, EC/TDS/NaCl, ORP, and temperature.

o Calibrate the pH probe using at least two buffers (pH 4.01 and 7.01, with 10.01 if needed).

o Calibrate EC/TDS with certified conductivity standards appropriate for your nutrient solution strength.

o Enable Automatic Temperature Compensation (ATC) for precise readings under greenhouse conditions.

2. Daily Monitoring

o Collect a nutrient solution sample from the reservoir or measure directly in the system.

o Record pH, EC, TDS, salinity, and temperature values to confirm proper nutrient balance.

o Use ORP measurements to evaluate the oxidation state of the solution when using sterilization systems (e.g., ozone or peroxide treatments).

3. Nutrient Management & Optimization

o Adjust pH with pH Up/Down solutions to keep levels within the optimal range for your crop.

o Modify EC/TDS values by increasing or diluting nutrient solution concentration.

o Track NaCl buildup to prevent salt stress in sensitive crops.

o Use temperature data to ensure that nutrient uptake is not limited by water temperature.

4. Data Logging & Trend Analysis

o Store up to 1,000 readings with calibration history for accurate long-term records.

o Export results via USB to monitor crop cycles, compare different feeding programs, and refine growing strategies.

o Use logged data to adjust irrigation timing, nutrient ratios, and seasonal growing parameters.

5. Best Practices

o Always rinse probes with deionized water between measurements to prevent contamination.

o Regularly recalibrate probes, especially when working with high-nutrient solutions.

o Store pH electrodes in proper storage solution to maintain accuracy and extend lifespan.

With its ability to measure pH, EC, TDS, NaCl, ORP, and temperature, combined with long-term data logging, the Milwaukee MW180 MAX Bench Meter is the ultimate solution for hydroponics, vertical farming, and greenhouse horticulture, helping growers maximize crop yields, prevent nutrient deficiencies, and maintain stable, healthy root zone conditions.

Aquaculture & Marine Systems

In aquaculture, aquariums, and marine systems, water stability is everything. Fish, shrimp, corals, and other aquatic species are highly sensitive to even small changes in pH, salinity, ORP, and temperature. The Milwaukee MW180 MAX Multi-Parameter Bench Meter gives aquaculture professionals and marine hobbyists the tools to maintain precise and stable water conditions, ensuring both the health of aquatic life and the success of commercial operations.

For fish farms, hatcheries, and shrimp ponds, monitoring pH and ORP is critical to managing oxygen levels, disinfection processes, and overall water quality. In marine aquariums and coral reef systems, measuring salinity (NaCl) and conductivity ensures proper osmotic balance, preventing stress or mortality in sensitive species. Temperature monitoring adds another layer of protection, since metabolic rates and breeding cycles in aquatic species are tightly regulated by water temperature.

The MW180 MAX also supports commercial seafood production, where water chemistry directly impacts growth rates, survival rates, and overall yield. By logging up to 1,000 records with GLP-compliant calibration data, aquaculture managers can track long-term water quality, optimize feeding schedules, and minimize disease outbreaks.

Whether used in KOI ponds, public aquariums, reef tanks, or intensive aquaculture farms, the MW180 MAX provides professional-grade, multi-parameter water quality testing that helps protect sensitive ecosystems and high-value aquatic stocks.

How to Use the MW180 MAX in Aquaculture & Marine Systems

1. Setup & Calibration

o Connect the electrodes for pH, ORP, EC/TDS/NaCl, and temperature.

o Calibrate pH with two or three buffers (pH 4.01, 7.01, 10.01).

o Calibrate salinity (NaCl) and conductivity probes with certified standards.

o Ensure ATC (Automatic Temperature Compensation) is active for reliable measurements.

2. Routine Monitoring

o Take water samples from ponds, tanks, or recirculating systems in clean containers.

o Insert electrodes into the sample or measure directly in the system water.

o Record pH, ORP, salinity, conductivity, and temperature values to ensure stable and optimal conditions.

3. Management & Optimization

o Adjust pH with safe buffering agents to maintain species-specific ranges.

o Use ORP values to optimize aeration and disinfection systems (ozone, UV, or chemical treatments).

o Monitor salinity (NaCl) to maintain proper osmotic balance for freshwater or marine species.

o Track temperature trends to align with feeding schedules, breeding cycles, or seasonal shifts.

4. Data Logging & Long-Term Control

o Log up to 1,000 measurements for long-term monitoring and performance tracking.

o Export results via USB for integration into aquaculture management software or compliance reports.

o Compare logged data over time to identify trends, prevent disease outbreaks, and improve survival rates.

5. Best Practices

o Rinse probes with fresh or deionized water after each use to prevent biofouling and salt deposits.

o Schedule regular calibration, especially in high-salinity environments where deposits can affect readings.

o Keep electrodes properly stored in their recommended solutions when not in use to extend lifespan.

By delivering accurate and stable monitoring of pH, ORP, salinity, conductivity, and temperature, the Milwaukee MW180 MAX Bench Meter empowers aquaculture farms, shrimp hatcheries, coral reef aquariums, and seafood production facilities to protect aquatic life, maintain long-term water stability, and maximize yield.

Industrial Process Control

In industrial water systems, even small imbalances in water chemistry can cause major problems such as corrosion, scaling, fouling, and system inefficiency. The Milwaukee MW180 MAX Multi-Parameter Bench Meter is designed to give engineers, plant operators, and quality managers a complete water analysis solution, combining pH, oxidation-reduction potential (ORP/mV), electrical conductivity (EC), total dissolved solids (TDS), salinity (NaCl), and temperature measurements in one robust instrument.

For cooling towers and boilers, accurate monitoring of pH, EC, and TDS ensures that water treatment programs are working effectively to prevent scale deposits, corrosion, and microbial growth. In chemical and pharmaceutical production, precise pH and conductivity control is vital for ensuring product quality, batch consistency, and compliance with GMP (Good Manufacturing Practice) standards.

Industries such as textiles, electronics, semiconductors, and food processing also rely on multi-parameter water testing to maintain strict quality control. For example, ultrapure water systems in electronics and semiconductor manufacturing require continuous monitoring of TDS and conductivity to guarantee that no impurities compromise sensitive processes.

With its data logging function (1,000 records with GLP-compliant calibration history) and USB connectivity, the MW180 MAX provides traceable records for audits, compliance, and predictive maintenance programs. This enables operators to detect water chemistry shifts early, adjust treatment dosing, and prevent costly downtime.

The MW180 MAX is more than just a bench meter – it is a strategic tool for industrial process optimization, helping companies reduce operational costs, extend equipment life, and maintain consistent quality in demanding environments.

How to Use the MW180 MAX in Industrial Process Control

1. Setup & Calibration

o Connect the pH, ORP, EC/TDS/NaCl, and temperature electrodes.

o Calibrate pH with appropriate buffer solutions (4.01, 7.01, and 10.01).

o Calibrate EC/TDS probes with certified conductivity standards suitable for industrial ranges.

o Enable Automatic Temperature Compensation (ATC) to ensure accuracy under varying process conditions.

2. Routine Testing

o Collect water samples from cooling towers, boilers, or process water loops in clean containers.

o Immerse probes in the sample or test directly if conditions allow.

o Record readings for pH, ORP, EC, TDS, salinity, and temperature to evaluate water treatment effectiveness.

3. Process Optimization & Quality Control

o Use pH readings to adjust chemical dosing in cooling water and boiler systems.

o Monitor EC and TDS levels to control scale buildup and prevent efficiency loss.

o Track ORP to evaluate oxidation levels and optimize disinfection processes.

o Use salinity (NaCl) measurements to monitor brine concentrations in food or chemical applications.

4. Data Logging & Compliance

o Store measurements in the meter’s internal memory for GLP-compliant traceability.

o Export via USB for integration into compliance reports, maintenance logs, and predictive analysis tools.

o Maintain a long-term database of water chemistry to anticipate treatment needs and reduce unplanned downtime.

5. Best Practices

o Rinse probes thoroughly after testing chemical-rich water samples to avoid buildup.

o Calibrate regularly, especially in environments with high dissolved solids.

o Store electrodes correctly in their recommended solutions to preserve sensitivity and lifespan.

With its multi-parameter measurement capability, high accuracy, and GLP-compliant data logging, the Milwaukee MW180 MAX Bench Meter is a vital instrument for industrial water treatment, manufacturing, pharmaceuticals, textiles, and electronics industries – ensuring water chemistry stays under control, processes remain efficient, and compliance standards are met.

Specialized Applications

Beyond standard water testing, the Milwaukee MW180 MAX Multi-Parameter Bench Meter is trusted in a variety of specialized industries and academic settings where precision, compliance, and reliability are non-negotiable.

Desalination Plants & Freshwater Recovery

In desalination facilities, monitoring salinity (NaCl), conductivity (EC), and TDS is critical to ensure efficient freshwater recovery. The MW180 MAX helps operators control brine concentration, evaluate reverse osmosis performance, and verify compliance with international drinking water standards. Accurate tracking of salt rejection rates and membrane efficiency reduces energy costs and improves system lifespan.

Pharmaceutical & Biotechnology

In pharmaceutical labs and biotech production, precise water quality control is mandatory for research integrity and product safety. The MW180 MAX provides multi-parameter monitoring of pH, EC, TDS, ORP, salinity, and temperature, supporting GMP, ISO, and FDA compliance. Whether used in purified water systems (PW/WFI), fermentation processes, or drug formulation, it ensures repeatable results and full traceability with GLP-compliant data logging.

Educational Training & University Labs

The MW180 MAX is a powerful teaching tool in academic laboratories and university training centers. By measuring six parameters at once, it allows students to understand the relationship between pH, conductivity, salinity, TDS, ORP, and temperature in applied water chemistry. Its intuitive interface and logging function make it ideal for teaching experiments, student research projects, and laboratory training courses.

Saltwater Food Processing & Brining Applications

In the food processing industry, precise control of NaCl levels in brines is essential for both safety and taste. The MW180 MAX supports cheese production, pickling, canning, and cured meats by ensuring consistent salinity, pH, and conductivity in preservation solutions. By maintaining strict control of brine chemistry, manufacturers can extend shelf life, achieve flavor consistency, and comply with HACCP food safety programs.