Your shopping cart is currently empty.

Milwaukee MW150 PRO pH/ORP/Temp Bench Meter – Precision for Professionals

In professional and research environments, accurate water parameter measurement is critical. Whether you are running a laboratory, monitoring water treatment processes, or ensuring product quality in food and beverage production, you need an instrument you can trust. The Milwaukee MW150 PRO Bench Meter is designed for precision, reliability, and ease of use.

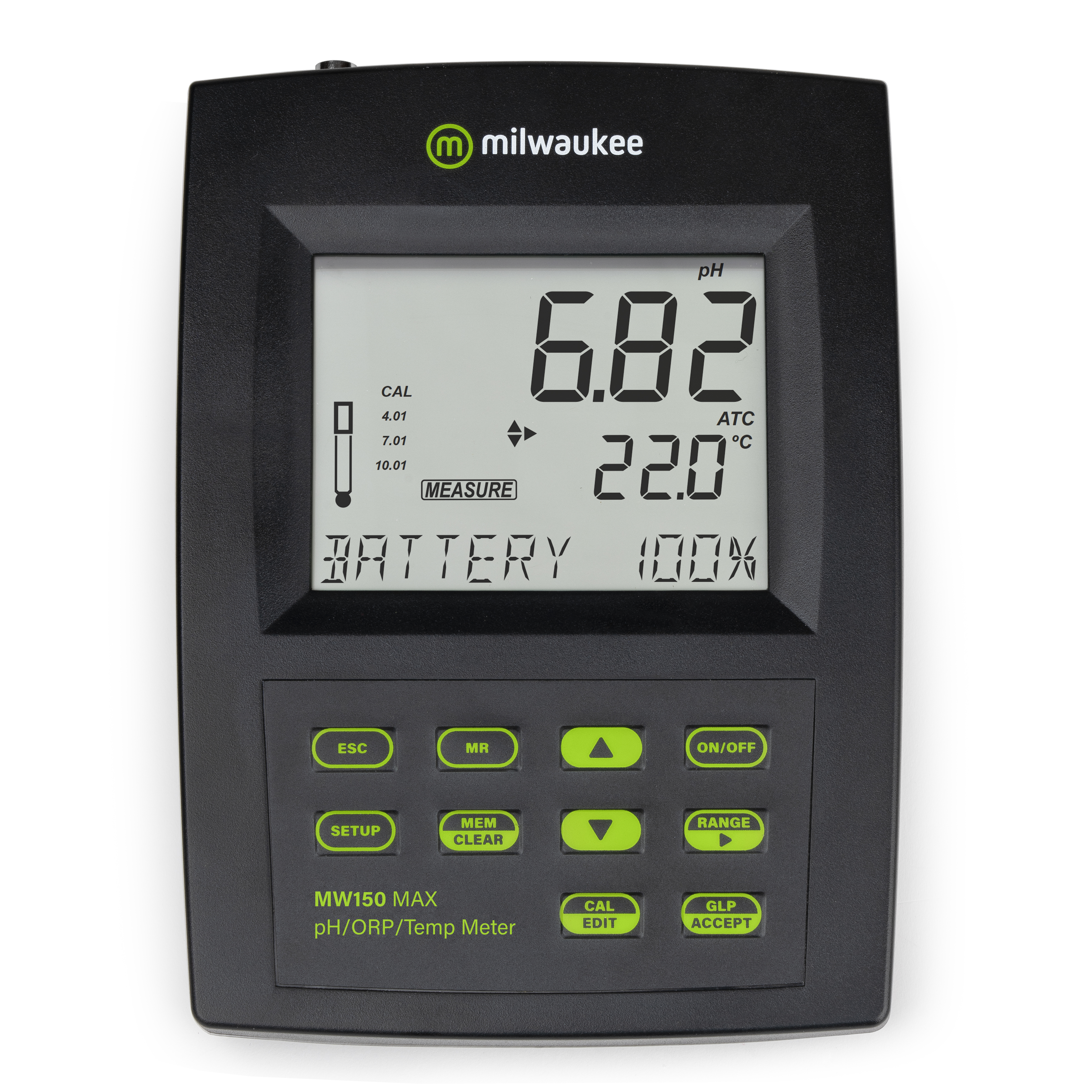

Built with professionals in mind, the MW150 PRO combines high accuracy (±0.01 pH) with robust functionality, offering pH, ORP (Oxidation-Reduction Potential), and temperature measurement in one compact benchtop solution. Its intuitive operation, large dual-level LCD display, and advanced features such as automatic temperature compensation, three-point calibration, and Good Laboratory Practice (GLP) data tracking make it a dependable partner for anyone who demands reliable results day after day.

From laboratories to industrial sites, this bench meter is trusted worldwide for its ability to deliver consistent, repeatable measurements – even in demanding applications and with challenging samples.

Why Choose the Milwaukee MW150 PRO?

- High Accuracy & Reliability – Delivers precision readings with ±0.01 pH accuracy, ±0.2 mV ORP accuracy, and ±0.4 °C temperature accuracy.

- Versatile Functionality – Measures pH, ORP, and temperature in one unit, with automatic temperature compensation for dependable results.

- Advanced Calibration – Three-point pH calibration with seven standard buffer options ensures flexibility and accuracy.

- Professional Electrode Design – Comes with a double-junction, refillable glass pH electrode, designed for durability and performance in demanding samples.

- GLP Compliance – Stores and recalls data for traceability, making it suitable for regulated industries and laboratories.

- User-Friendly Operation – Large, easy-to-read dual-level LCD, stability indicators, and intuitive keys simplify use.

- Durable & Practical – Built for everyday lab and field use, with rugged housing, auto-off function, and a long-lasting power supply.

Versatile Applications of MW150 PRO

Laboratories & Research

• High-precision testing of pH, ORP, and temperature

• Ideal for education, scientific experiments, and regulated industriesWater Treatment & Environmental Monitoring

• Ensuring compliance in drinking water and wastewater treatment

• Monitoring lakes, rivers, and groundwater samplesFood & Beverage Production (Wine, Beer, Dairy, General Foods)

• Monitoring pH during fermentation and processing

• Ensuring product quality, taste, and safetyHydroponics & Horticulture

• Controlling nutrient solution pH for healthy crop growth

• Preventing nutrient lockout and yield lossAquariums & Aquaculture (Fish, KOI, Shrimp, Coral)

• Maintaining stable pH and ORP for aquatic life

• Supporting sensitive and high-value species healthIndustrial Water Monitoring

• Managing pH and ORP in cooling towers, boilers, and process water

• Supporting system efficiency and corrosion preventionPools & Spas

• Monitoring pH and ORP for safe, clear, and sanitized water

Proper Care & Maintenance

The performance of your MW150 PRO depends heavily on proper electrode care. pH and ORP electrodes naturally age and require attention, but with the right maintenance, you can extend their lifespan and ensure consistent accuracy.

Storage

- Always keep the pH electrode hydrated in storage solution or calibration buffer.

- Never store in distilled or deionized water, which will damage the electrode.

- Store upright with the protective cap filled with storage solution.

Cleaning

- Residues, especially from samples with organic or oily content, can clog the reference junction.

- Regularly soak the electrode in cleaning solution to restore performance.

Calibration

- Calibrate frequently (ideally before each use) to account for natural sensitivity changes over time.

- Always calibrate after cleaning or after prolonged storage.

Handling

- Avoid touching or scratching the sensitive glass bulb.

- Rinse the electrode with distilled water between samples to prevent contamination.

By following these simple steps, you will maximize the life of your probe and maintain the accuracy that Milwaukee PRO meters are known for.

Enhance your testing with the Milwaukee MW150 PRO – the professional choice for accurate, reliable, and easy-to-use pH, ORP, and temperature measurement.

Specifications

Application

Laboratories & Research

In laboratories and research environments, precision and repeatability are essential. The Milwaukee MW150 PRO is engineered to meet the rigorous demands of professional scientists, educators, and students. With its ±0.01 pH accuracy, ±0.2 mV ORP accuracy, and advanced temperature compensation, the MW150 PRO delivers reliable data you can trust for sensitive experiments and regulated studies.

For scientific analysis, even small pH or ORP fluctuations can affect outcomes. The MW150 PRO minimizes these risks by offering:

- Three-point pH calibration with seven standard buffer options for maximum flexibility.

- GLP-compliant data tracking, ensuring calibration and measurement history can be recorded and traced – a must for quality assurance and compliance.

- Durable, double-junction electrodes designed to handle a variety of sample types, from clean laboratory water to more complex or viscous solutions.

In education and training labs, the MW150 PRO shines as a teaching tool. Its intuitive design, large dual-level LCD, and stability indicators make it easy for students to learn proper measurement techniques. Educators can rely on its robustness and accuracy to demonstrate key concepts in chemistry, biology, and environmental science without constant recalibration or technical interruptions.

Whether used in university research labs, quality control departments, or classroom experiments, the MW150 PRO provides consistency, accuracy, and confidence in every test.

How to Use the MW150 PRO

Using the MW150 PRO Bench Meter is straightforward, but following the correct steps ensures accuracy and long electrode life:

1. Preparation

o Plug in the pH/ORP electrode and temperature probe.

o Rinse the electrode with distilled water to remove contaminants.

o Make sure the electrode is hydrated in storage solution before use.

2. Calibration

o Switch on the meter and allow it to stabilize.

o Select calibration mode and use fresh standard buffers (e.g., pH 4.01, 7.01, 10.01).

o Perform up to a three-point calibration for the highest accuracy.

o For ORP, calibrate using a standard ORP solution if required.

3. Measurement

o Immerse the electrode in the sample, ensuring the sensing bulb and junction are fully covered.

o Wait for the stability indicator to confirm a steady reading.

o Record the pH, ORP, and temperature values displayed on the LCD.

4. After Use

o Rinse the electrode with distilled water between samples.

o Return the electrode to its storage solution when finished.

o Regularly check calibration and recalibrate as needed for accuracy.

By following these steps, laboratories and research facilities can ensure precise, repeatable measurements while extending the life of their electrodes.

Water Treatment & Environmental Monitoring

Water quality directly impacts public health, industry, and the environment. From ensuring safe drinking water to maintaining compliance in wastewater discharge, precise pH and ORP monitoring is essential. The Milwaukee MW150 PRO provides professionals with the accuracy and reliability required for both routine monitoring and regulatory compliance.

In drinking water treatment, pH and ORP readings are critical for evaluating disinfection effectiveness and controlling corrosion in distribution systems. Accurate monitoring helps utilities maintain consistent water chemistry, safeguard infrastructure, and ensure that consumers receive clean and safe water.

In wastewater treatment, pH is carefully controlled during neutralization, precipitation, and biological processes. ORP provides insight into oxidation and reduction reactions, making it a valuable indicator of biological activity and disinfection potential. The MW150 PRO supports operators by delivering dependable data, enabling timely adjustments to treatment processes and reducing risks of non-compliance.

For environmental monitoring, researchers and regulators use the MW150 PRO to track the health of lakes, rivers, and groundwater. pH shifts can signal pollution or ecological stress, while ORP values reveal changes in water chemistry such as oxygen availability or contamination levels. With its rugged electrode design and precise temperature compensation, the MW150 PRO is equally effective in the lab and the field, ensuring that environmental data is trustworthy and reproducible.

By combining precision with robust construction, the MW150 PRO becomes a versatile tool for environmental scientists, water utility technicians, and compliance officers who need data they can depend on to protect both people and ecosystems.

How to Use the MW150 PRO in Water Treatment & Environmental Monitoring

1. Setup & Preparation

o Connect the pH electrode, ORP electrode, and temperature probe.

o Rinse probes with distilled water before each measurement to avoid contamination.

o Place the meter on a stable, clean bench or use it in a controlled field setting.

2. Calibration

o Calibrate pH using fresh buffer solutions (commonly pH 4.01, 7.01, and 10.01) for multi-point accuracy.

o For ORP, calibrate with a standard ORP solution (e.g., 220 mV or 470 mV, depending on application).

o Ensure calibration is performed at the start of each day or when changing measurement conditions.

3. Measurement in Treatment Facilities

o Submerge the pH or ORP electrode into the sample (influent, effluent, or intermediate process stream).

o Wait for the stability icon to confirm a steady reading.

o Record values for process adjustments or compliance logs.

o Use temperature readings for proper compensation and chemical dosing adjustments.

4. Measurement in Environmental Field Testing

o Collect samples in clean containers from lakes, rivers, or groundwater wells.

o Immerse the electrodes fully, avoiding air bubbles near the sensing area.

o Allow the reading to stabilize before recording pH, ORP, and temperature.

o For multiple sites, rinse probes thoroughly between samples to prevent cross-contamination.

5. After Use

o Rinse probes with distilled water after each measurement.

o Store the pH electrode in storage solution to keep it hydrated.

o Clean electrodes regularly, especially after measuring wastewater or organic-rich samples.

By following these practices, operators and researchers can achieve highly accurate, repeatable results while extending the lifetime of their electrodes – ensuring reliable water quality data for treatment optimization and environmental protection.

Food & Beverage (Wine, Beer, Dairy, General Foods)

In the food and beverage industry, pH control is one of the most critical quality parameters. Even small deviations can affect flavor, texture, safety, and shelf life. The Milwaukee MW150 PRO Bench Meter provides the accuracy and reliability professionals need to safeguard their processes and products.

In winemaking and brewing, pH plays a key role in fermentation, influencing yeast activity, microbial stability, and final taste. Proper ORP (oxidation-reduction potential) control helps monitor oxygen levels, which are essential for managing oxidation and ensuring product stability. The MW150 PRO gives vintners and brewers confidence that each batch maintains consistency and quality.

In the dairy industry, pH monitoring is essential for processes like cheese making, yogurt fermentation, and pasteurization. Even slight shifts can change texture or reduce product safety. The MW150 PRO ensures dairy producers can maintain precise conditions for microbial activity and product stability.

In general food processing, from sauces and condiments to baked goods and canned products, pH measurement supports food safety by controlling microbial growth and ensuring compliance with regulatory standards. Accurate readings allow manufacturers to verify HACCP (Hazard Analysis and Critical Control Points) protocols and meet industry requirements.

By combining high precision, GLP traceability, and robust electrodes that handle both clean and complex food samples, the MW150 PRO is a trusted instrument for producers who cannot afford inconsistencies or product recalls.

How to Use the MW150 PRO in Food & Beverage Applications

1. Setup & Preparation

o Connect the pH electrode, ORP electrode (if required), and temperature probe.

o Rinse electrodes with distilled water before use.

o For viscous samples (e.g., dairy, sauces), ensure the electrode tip is clean and free of residues.

2. Calibration

o Calibrate the pH meter daily using fresh standard buffer solutions (commonly pH 4.01, 7.01, and 10.01).

o If ORP monitoring is needed (e.g., in wine/beer oxidation control), calibrate with a standard ORP solution.

o Always calibrate before critical testing or after cleaning.

3. Measurement in Production

o Submerge the electrode in the product sample (wine, beer wort, milk, yogurt mix, sauce, etc.).

o Ensure the sensing bulb and junction are fully immersed, avoiding bubbles or foam.

o Allow readings to stabilize before recording pH, ORP, and temperature.

o Use temperature readings to verify compensation and maintain consistent processing conditions.

4. Monitoring & Quality Control

o For fermentation: record pH and ORP regularly to track microbial activity and fermentation progress.

o For finished products: test batch samples to verify consistency with previous production runs.

o For safety: confirm pH levels are within required ranges to inhibit harmful microbial growth.

5. After Use

o Rinse the electrode thoroughly with distilled water.

o For samples with fats, proteins, or sugars (e.g., dairy or sauces), clean the electrode in a mild cleaning solution to prevent clogging.

o Store the electrode in storage solution to maintain hydration and sensitivity.

With these steps, food and beverage producers can ensure repeatable, precise measurements that protect product quality, meet regulatory standards, and safeguard consumer trust.

Hydroponics & Horticulture

In hydroponic systems and horticulture, pH control is the cornerstone of healthy plant growth. Nutrient solutions must remain within a narrow pH range for plants to absorb essential elements like nitrogen, phosphorus, potassium, and micronutrients. Even small pH imbalances can cause nutrient lockout, where plants are unable to take up vital nutrients, leading to stunted growth, yellowing leaves, or reduced yields.

The Milwaukee MW150 PRO Bench Meter gives growers the accuracy (±0.01 pH) and stability needed to fine-tune nutrient solutions with confidence. Its automatic temperature compensation ensures readings remain reliable even when solution temperatures fluctuate throughout the day. For operations using advanced fertigation systems or recirculating hydroponic setups, the MW150 PRO helps growers maintain the optimal root-zone environment for consistent harvest quality and maximum productivity.

In soil-based horticulture, the MW150 PRO is equally valuable for testing irrigation water and soil slurry samples. Monitoring pH and ORP helps identify potential imbalances, improve fertilizer strategies, and ensure that crops are thriving under the right growing conditions.

Whether you’re managing a commercial greenhouse, a vertical farm, or a small hydroponic setup, the MW150 PRO provides professional-grade control over one of the most important variables in plant health.

How to Use the MW150 PRO in Hydroponics & Horticulture

1. Setup & Preparation

o Connect the pH electrode, ORP electrode (optional), and temperature probe.

o Rinse the electrodes with distilled water before immersion.

o Ensure the pH probe has been stored in storage solution and is hydrated before use.

2. Calibration

o Calibrate daily or before critical measurements using standard buffer solutions (typically pH 4.01, 7.01, and 10.01).

o Multi-point calibration ensures maximum accuracy across the pH range of nutrient solutions.

o Always calibrate after cleaning or after long storage periods.

3. Measuring Nutrient Solutions

o Collect a sample of your nutrient solution in a clean container.

o Immerse the pH electrode fully, ensuring the sensing bulb and junction are covered.

o Wait for the stability indicator to confirm a steady reading.

o Record pH, ORP (if applicable), and temperature values.

4. Adjusting pH

o If pH is too high (alkaline), carefully add pH-down solution (acid).

o If pH is too low (acidic), add pH-up solution (base).

o Mix thoroughly and re-test until the solution is in the optimal range (commonly 5.5–6.5, depending on the crop).

5. Monitoring in Soil-Based Horticulture

o Prepare a soil slurry (1 part soil, 2 parts distilled water).

o Immerse the electrode into the slurry and allow it to stabilize.

o Use results to adjust irrigation water or fertilizer applications.

6. After Use

o Rinse electrodes with distilled water after each measurement.

o For nutrient-rich solutions, clean the electrode periodically in cleaning solution to prevent buildup.

o Store the electrode in storage solution to maintain sensitivity and extend lifespan.

By integrating the MW150 PRO into daily monitoring routines, growers can prevent nutrient imbalances, reduce crop stress, and achieve higher yields with healthier, more resilient plants.

Aquariums & Aquaculture (Fish, KOI, Shrimp, Coral)

In aquariums and aquaculture, stable water chemistry is the foundation of aquatic life health. Fish, shrimp, corals, and other species thrive only within narrow pH and ORP ranges. Even minor fluctuations can cause stress, reduce growth rates, increase disease susceptibility, or in severe cases, lead to mortality.

The Milwaukee MW150 PRO Bench Meter provides aquarists, koi pond keepers, and aquaculture professionals with the precision (±0.01 pH) and reliability needed to safeguard water quality. With its automatic temperature compensation, the MW150 PRO ensures accurate results even when water temperatures fluctuate – a common challenge in both indoor aquariums and outdoor ponds.

- In freshwater aquariums and koi ponds, maintaining a stable pH is essential to reduce stress and prevent harmful ammonia toxicity. ORP readings provide insights into water cleanliness and the effectiveness of filtration or UV sterilization systems.

- In marine aquariums and reef tanks, corals and invertebrates are particularly sensitive to small pH shifts. ORP measurements help aquarists monitor oxidation levels, supporting stable oxygenation and the breakdown of organic waste.

- In commercial aquaculture, such as shrimp or fish farms, daily monitoring of pH and ORP helps operators maintain conditions that maximize growth, reduce stress, and ensure higher survival rates – directly impacting profitability.

By using the MW150 PRO, aquarists and aquaculture professionals can maintain balanced, healthy environments where aquatic organisms thrive.

How to Use the MW150 PRO in Aquariums & Aquaculture

1. Setup & Preparation

o Connect the pH electrode, ORP electrode, and temperature probe.

o Rinse the probes with distilled water before use to remove contaminants.

o Ensure the pH electrode is hydrated in storage solution before measurement.

2. Calibration

o Calibrate pH daily using fresh buffer solutions (commonly pH 4.01, 7.01, and 10.01).

o Calibrate the ORP electrode with a standard ORP solution (e.g., 220 mV or 470 mV).

o Always recalibrate after cleaning or extended storage.

3. Measuring Aquarium or Pond Water

o Collect a sample in a clean container, or immerse the probes directly into the tank/pond.

o Ensure the sensing bulb of the electrode is fully submerged.

o Allow the reading to stabilize before recording pH, ORP, and temperature values.

o Compare results with the ideal ranges for your species (e.g., 6.5–7.5 for freshwater fish, 8.0–8.4 for reef tanks).

4. Monitoring & Adjusting

o For low pH: gradually add a pH buffer or adjust carbonate hardness (KH).

o For high pH: use pH-lowering agents or natural methods (driftwood, peat, etc.) depending on the system.

o For ORP management: ensure proper filtration, aeration, or use of ozone/UV systems.

o Track results regularly to detect and correct shifts before they stress the livestock.

5. After Use

o Rinse electrodes with distilled water after each test.

o For saltwater or organic-rich systems, clean electrodes regularly in a cleaning solution to prevent buildup.

o Store electrodes in storage solution to maintain sensitivity and accuracy.

By integrating the MW150 PRO into routine water checks, aquarists and aquaculture operators gain peace of mind knowing they can detect and correct problems early – protecting delicate species, supporting growth, and ensuring long-term system stability.

Industrial Water Monitoring

In industrial operations, water is more than just a utility – it is a critical part of production and infrastructure. Cooling towers, boilers, and process water systems all depend on carefully controlled water chemistry to function safely and efficiently. Two of the most important parameters to manage are pH and ORP (oxidation-reduction potential).

The Milwaukee MW150 PRO Bench Meter provides industrial operators with the high accuracy and reliability required to monitor these parameters. Maintaining proper pH levels is essential to prevent scaling, corrosion, and reduced efficiency in boilers and cooling systems. ORP monitoring helps evaluate oxidizing agents (such as chlorine or ozone) used for disinfection, ensuring that microbial growth is controlled without overdosing chemicals.

- In cooling towers, pH control minimizes scale buildup and corrosion in pipes, heat exchangers, and pumps, directly improving equipment lifespan and reducing maintenance costs.

- In boiler systems, precise pH measurement ensures that water chemistry is optimized to prevent metal corrosion and steam contamination.

- In industrial process water, consistent pH and ORP control ensures compliance with safety standards, improves chemical dosing efficiency, and protects downstream equipment.

By providing fast, precise, and GLP-traceable results, the MW150 PRO supports engineers, plant operators, and quality managers in keeping operations safe, efficient, and compliant.

How to Use the MW150 PRO in Industrial Water Monitoring

1. Setup & Preparation

o Connect the pH electrode, ORP electrode, and temperature probe.

o Rinse the probes with distilled water before use.

o For highly treated or chemical-rich samples, ensure electrodes are clean and in good condition before measurement.

2. Calibration

o Perform a three-point calibration for pH (using buffers such as 4.01, 7.01, and 10.01) for maximum accuracy.

o Calibrate ORP with a standard solution (220 mV or 470 mV) depending on process requirements.

o Recalibrate daily or before critical compliance testing.

3. Measuring in Cooling Towers & Boilers

o Collect a representative water sample in a clean container.

o Immerse the electrodes, ensuring full contact with the liquid.

o Allow the stability indicator to confirm a steady reading.

o Record pH, ORP, and temperature values for system logs or compliance reports.

4. Process Adjustments

o Low pH (acidic water): Add corrosion inhibitors or alkaline chemicals (such as sodium hydroxide) to raise pH.

o High pH (alkaline water): Add acid treatments (such as sulfuric acid) to bring pH down and prevent scaling.

o Low ORP: Increase oxidizing agents (chlorine, ozone, etc.) to improve microbial control.

o High ORP: Reduce oxidizing chemical dosing to prevent excess corrosion or byproducts.

5. After Use

o Rinse probes thoroughly with distilled water after each measurement.

o For samples with high chemical content, soak electrodes periodically in cleaning solution to prevent buildup.

o Store electrodes in storage solution when not in use to keep them hydrated and accurate.

By incorporating the MW150 PRO into daily monitoring routines, industrial facilities can optimize chemical dosing, extend equipment life, reduce downtime, and maintain regulatory compliance – all while ensuring safe and efficient water system operation.

Pools & Spas

In swimming pools and spas, water balance is essential for both safety and comfort. Two of the most critical parameters to control are pH and ORP (oxidation-reduction potential). Together, they determine how effectively sanitizers like chlorine or bromine work, how comfortable the water feels to bathers, and how well equipment is protected from corrosion or scale buildup.

The Milwaukee MW150 PRO Bench Meter provides pool and spa operators with laboratory-grade precision to ensure water is safe, clean, and inviting.

- pH Control: Water that is too acidic (low pH) can cause eye and skin irritation, corrode pool equipment, and reduce liner life. Water that is too alkaline (high pH) can lead to cloudy water, scaling, and reduced sanitizer efficiency.

- ORP Monitoring: ORP is a direct measure of the water’s disinfection potential. A proper ORP reading ensures that chlorine or bromine is active and killing harmful bacteria, viruses, and algae effectively.

Whether you manage a public swimming pool, spa facility, or private hot tub, maintaining stable pH and ORP protects bathers, preserves equipment, and ensures compliance with local health standards. The MW150 PRO delivers fast, accurate results that let you act before imbalances become costly problems.

How to Use the MW150 PRO in Pools & Spas

1. Setup & Preparation

o Connect the pH electrode, ORP electrode, and temperature probe.

o Rinse probes with distilled water before use.

o Collect a water sample from the pool or spa in a clean container, ideally from elbow depth away from jets or inlets.

2. Calibration

o Calibrate the pH electrode using standard buffer solutions (pH 4.01, 7.01, and 10.01) for maximum accuracy.

o Calibrate the ORP electrode with a standard solution (220 mV or 470 mV).

o Perform calibration regularly, especially during peak swimming season.

3. Measurement

o Immerse the electrodes into the water sample, ensuring the sensing tips are fully submerged.

o Wait for the stability indicator to confirm a steady reading.

o Record pH, ORP, and temperature values.

4. Interpreting Results & Adjustments

o Ideal pool pH: 7.2–7.6

o Ideal spa pH: 7.2–7.8

o Ideal ORP range: 650–750 mV for effective sanitation (may vary by regulation and sanitizer type)

o If pH is outside the ideal range, adjust with pH-up (alkaline agent) or pH-down (acid).

o If ORP is low, increase sanitizer dosing; if ORP is too high, reduce sanitizer levels to avoid excess chemical exposure.

5. After Use

o Rinse electrodes thoroughly with distilled water after each measurement.

o For spa water (which often has higher organic load and temperature), clean electrodes more frequently with cleaning solution.

o Store pH electrodes in storage solution to prevent drying out.

By incorporating the MW150 PRO into regular pool and spa maintenance, operators can maintain sparkling water, protect swimmers’ health, and extend the life of pool equipment – ensuring the water is always safe and enjoyable.