Your shopping cart is currently empty.

Milwaukee MA871 Digital Brix Refractometer – Fast & Accurate Brix Testing for Food & Beverage Professionals

The Milwaukee MA871 Digital Brix Refractometer delivers precise, reliable, and fast Brix measurements, making it the ideal tool for food, beverage, and agricultural applications. Whether you're a brewer, winemaker, maple syrup producer, or food quality professional, this digital refractometer ensures quick, accurate readings with minimal sample size.

With an easy-to-use design and automatic temperature compensation (ATC) the MA871 provides professional-grade results without the need for manual calculations or optical guesswork. Say goodbye to outdated refractometers and experience the speed, precision, and convenience of digital Brix testing.

Why Choose the Milwaukee MA871?

High Accuracy – 0 to 85% Brix range with ±0.2%

precision.

Fast & Reliable – Get results in under 2 seconds.

Easy to Use – Simple two-button operation for hassle-free

testing.

Minimal Sample Needed – Only 2-3 drops required for measurement.

Automatic Temperature Compensation (ATC) – Ensures consistent accuracy.

Long Battery Life – Battery indicator & automatic shut-off included.

Versatile Applications – Ideal for brewing, winemaking, food

processing, and agriculture.

Applications

Winemaking & brewing

In winemaking and brewing, the Milwaukee MA871 Digital Brix Refractometer is used to measure the sugar content in grape juice (must) or brewing wort. This measurement is crucial because the amount of sugar present determines the potential alcohol content of the final product.

Hydroponics & Greenhouses

Optimizing Nutrient Solutions for Healthy Plant Growth

In hydroponics and greenhouse cultivation, the Milwaukee MA871 Digital Brix Refractometer is used to measure the sugar content in plant sap or nutrient solutions. This helps growers monitor plant health, optimize feeding strategies, and ensure maximum crop yield.

Fruit & Vegetable Growers

For farmers, orchard managers, and agricultural professionals, the Milwaukee MA871 Digital Brix Refractometer is an essential tool for accurately measuring sugar content in fruits and vegetables. This allows growers to determine optimal harvest time, ensure consistent quality, and enhance overall crop value. Whether testing grapes, tomatoes, melons, citrus fruits, or berries, the MA871 provides precise Brix measurements to maintain high industry standards.

Food & Beverage Industry

In the food and beverage industry, maintaining consistent sugar content is critical for quality control, taste, and product stability. The Milwaukee MA871 Digital Brix Refractometer provides quick and precise Brix measurements, allowing manufacturers to standardize formulations, improve production efficiency, and meet consumer expectations. Whether working with beverages, dairy, sauces, or processed foods, the MA871 helps ensure every batch meets strict industry standards.

Industrial & Laboratory Use

In industrial and laboratory settings, precise Brix measurements are essential for quality control, research, and process optimization. The Milwaukee MA871 Digital Brix Refractometer provides fast, accurate, and reliable sugar concentration readings, ensuring consistency across chemical formulations, pharmaceutical production, and food science research. With its digital precision and user-friendly design, the MA871 is an ideal tool for R&D labs, quality assurance teams, and industrial manufacturers working with sugar-based solutions.

Maintenance tips

1. Keep the Prism Clean

- Wipe the prism regularly with a soft, lint-free cloth. This prevents any residue, dust, or liquid from affecting the accuracy of readings.

- Use distilled water to clean the prism when necessary, ensuring that no chemicals or harsh cleaners are used, which could damage the instrument.

2. Calibrate the Instrument Periodically

- Calibrate the MA871 regularly using the provided calibration standards with distilled or deionized water. Calibration should be done in the same temperature range as your samples for best results.

- Calibration should be performed daily, before measurements are made, when the battery has been replaced, or between a long series of measurements.

- Recalibrate if the readings deviate from known standards or if the instrument has been exposed to extreme conditions.

3. Store Properly

- When not in use, store the MA871 in a dry, cool place away from direct sunlight or excessive heat, which could damage the internal components.

- Use the protective cover to shield the refractometer from dust, dirt, and physical damage.

4. Avoid Extreme Conditions

- Protect from moisture: Avoid exposing the refractometer to extreme humidity, as moisture could damage the sensitive electronics.

- Temperature sensitivity: Keep the device within its recommended operating temperature range for accurate readings.

5. Check for Leaks

- Ensure that the sample chamber is properly sealed before taking measurements to prevent liquid from leaking into the device, which could cause internal damage.

6. Replace the Battery When Needed

- Monitor the battery life: If the display starts to dim or the instrument behaves erratically, replace the battery to ensure consistent performance.

- Always use appropriate battery types to avoid malfunction.

Order the Milwaukee MA871 Today!

Upgrade to fast, precise Brix testing and take control of your brewing, food production, or agricultural processes.

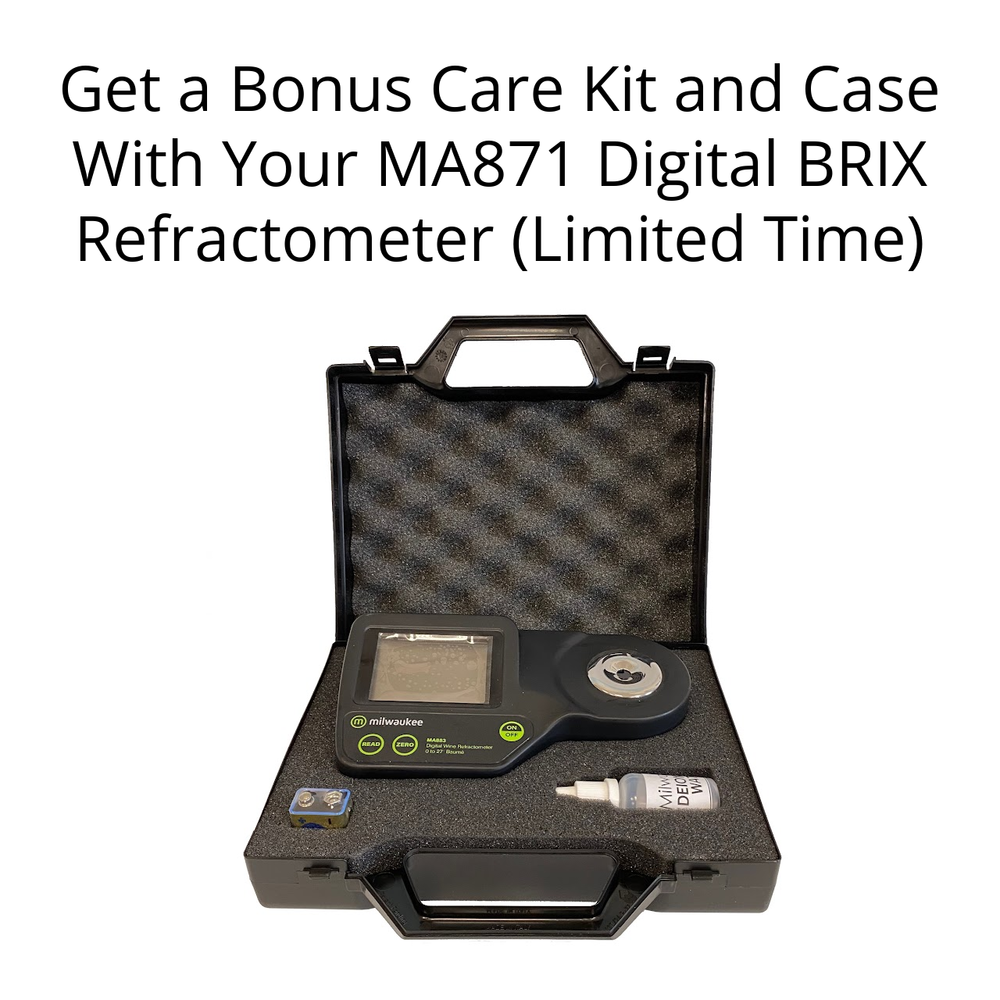

If you order the MA871 you will get a free hard carrying case (MA752) with your purchase!

Specifications

Application

Winemaking & brewing

In winemaking and brewing, the Milwaukee MA871 Digital Brix Refractometer is used to measure the sugar content in grape juice (must) or brewing wort. This measurement is crucial because the amount of sugar present determines the potential alcohol content of the final product.

How It Works:

- The MA871 measures the sugar concentration in the liquid and provides a Brix (%) reading.

- Brix represents grams of sugar per 100 grams of solution (e.g., 20° Brix means 20g of sugar in 100g of liquid).

- Fermentation occurs when yeast converts these sugars into alcohol and carbon dioxide.

Why It’s Important:

- Winemakers use Brix readings to predict the final alcohol by volume (ABV) in wine. A typical conversion factor is 0.55 (e.g., 22° Brix × 0.55 ≈ 12.1% ABV).

- Brewers measure Brix before and after fermentation to monitor the progress and ensure proper attenuation (fermentation completion).

- It helps in harvest timing—grapes need to be picked at optimal sugar levels for the desired wine style.

How It Helps:

· Brewers – Easily measure wort sugar levels to determine potential alcohol content and track fermentation progress.

· Winemakers – Accurately determine grape ripeness and predict alcohol content.

· Cider & Mead Makers – Ensure balanced sugar levels for fermentation success.

How to Use:

- Calibrate with distilled water.

- Place 2-3 drops of sample in the well.

- Close the cover and read the digital display.

Hydroponics & Greenhouses

Optimizing Nutrient Solutions for Healthy Plant Growth

In hydroponics and greenhouse cultivation, the Milwaukee MA871 Digital Brix Refractometer is used to measure the sugar content in plant sap or nutrient solutions. This helps growers monitor plant health, optimize feeding strategies, and ensure maximum crop yield.

How It Works:

- The MA871 provides a Brix (%) reading, indicating the amount of dissolved sugars in a liquid.

- Measuring plant sap Brix levels gives insight into the plant’s overall health, nutrient uptake, and stress levels.

- It can also be used to check the concentration of nutrient solutions to maintain proper feeding schedules.

Why It’s Important:

- Higher Brix levels in plant sap indicate better photosynthesis, stronger resistance to pests and diseases, and improved crop quality.

- Helps growers adjust fertilizer and water ratios for optimal nutrient absorption.

- Prevents over- or under-fertilization, reducing waste and improving sustainability.

How It Helps:

· Hydroponic Growers – Monitor plant sap Brix levels to assess nutrient uptake and overall plant health.

· Greenhouse Farmers – Optimize nutrient solution concentrations to promote stronger growth and disease resistance.

· Crop Consultants – Use Brix readings to evaluate plant vitality and fine-tune fertilization programs.

How to Use:

- Calibrate with distilled water.

- Place 2-3 drops of plant sap or nutrient solution in the well.

- Close the cover and read the digital display for an instant Brix measurement.

Fruit & Vegetable Growers

For farmers, orchard managers, and agricultural professionals, the Milwaukee MA871 Digital Brix Refractometer is an essential tool for accurately measuring sugar content in fruits and vegetables. This allows growers to determine optimal harvest time, ensure consistent quality, and enhance overall crop value. Whether testing grapes, tomatoes, melons, citrus fruits, or berries, the MA871 provides precise Brix measurements to maintain high industry standards.

Why It’s Important:

- Harvest Timing – Fruits and vegetables reach peak flavor and market readiness when their sugar content is at the ideal level. A Brix reading helps determine the best time to harvest.

- Quality Control – Consistent sweetness and sugar levels are key for fruit processors, juice manufacturers, and fresh produce sellers.

- Market Value – Higher sugar content often means better taste, longer shelf life, and premium pricing.

Key Benefits:

· Monitor ripeness to optimize harvesting time and reduce losses.

· Ensure consistent sweetness for fruit processing, juice production, and fresh market sales.

· Improve quality control in commercial agriculture and food production.

How to Use:

- Extract juice from the fruit by crushing or squeezing.

- Apply 2-3 drops to the sensor well of the refractometer.

- Close the cover and read the digital display to obtain the Brix value.

Food & Beverage Industry

In the food and beverage industry, maintaining consistent sugar content is critical for quality control, taste, and product stability. The Milwaukee MA871 Digital Brix Refractometer provides quick and precise Brix measurements, allowing manufacturers to standardize formulations, improve production efficiency, and meet consumer expectations. Whether working with beverages, dairy, sauces, or processed foods, the MA871 helps ensure every batch meets strict industry standards.

Why It’s Important:

- Consistency in Production – Standardized Brix levels ensure uniform taste, texture, and sweetness in every batch.

- Regulatory Compliance – Many food products must meet specific sugar content regulations for labeling and quality control.

- Cost Control & Efficiency – Helps manufacturers optimize ingredient usage, reducing excess sugar while maintaining ideal flavor.

Industry Uses:

· Soft Drinks & Juices – Maintain ideal sugar levels in formulations for balanced taste and shelf stability.

· Dairy Products – Ensure proper Brix levels in ice cream, yogurt, and flavored milk for texture and mouthfeel.

· Syrups & Jams – Monitor sugar concentration to achieve the desired viscosity, sweetness, and preservation.

· Sauces & Condiments – Balance sugar content for taste consistency and texture in products like ketchup, BBQ sauce, and salad dressings.

· Confectionery & Baked Goods – Verify sugar content in glazes, fillings, and dough mixtures to maintain recipe precision.

How to Use:

- Place a small sample of the beverage, syrup, or food liquid onto the refractometer’s prism.

- Press "READ" to obtain an instant digital Brix value.

- Compare the reading to target specifications and adjust sugar content if needed for product consistency.

Industrial & Laboratory Use

In industrial and laboratory settings, precise Brix measurements are essential for quality control, research, and process optimization. The Milwaukee MA871 Digital Brix Refractometer provides fast, accurate, and reliable sugar concentration readings, ensuring consistency across chemical formulations, pharmaceutical production, and food science research. With its digital precision and user-friendly design, the MA871 is an ideal tool for R&D labs, quality assurance teams, and industrial manufacturers working with sugar-based solutions.

Why It’s Important:

- Research & Development (R&D) – Helps scientists and technicians analyze sugar content in new formulations.

- Quality Control & Compliance – Ensures consistency in product batches and adherence to industry regulations.

- Process Optimization – Used in industrial manufacturing to maintain stable sugar concentrations for efficiency and performance.

Industry Uses:

· Pharmaceutical Industry – Measures sugar levels in liquid medicines, syrups, and IV solutions for precise formulation.

· Chemical Manufacturing – Ensures sugar-based compounds meet required specifications for production.

· Food Science & Research – Supports nutritional analysis and ingredient standardization in lab testing.

· Cosmetic & Personal Care – Evaluates sugar-based ingredients in lotions, serums, and beauty formulations.

· Quality Assurance Labs – Provides accurate, repeatable Brix readings for product testing.

How to Use:

- Place a small sample of the liquid onto the refractometer’s prism.

- Press "READ" to obtain an instant digital Brix value.

- Compare results with target specifications for quality control or research analysis.